Warehouse Space Always Running Short? Let Cantilever Racking Solve Your Storage Challenges

Sep 18 , 2025

Ever feel overwhelmed by the sight of long steel pipes, wooden boards, and irregularly shaped items scattered chaotically across your warehouse floor? We understand that anxiety all too well—until you discover cantilever racking.

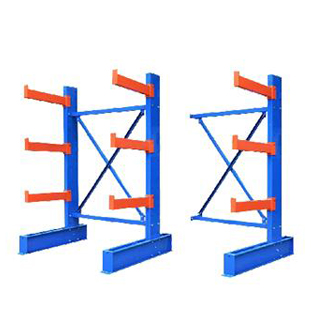

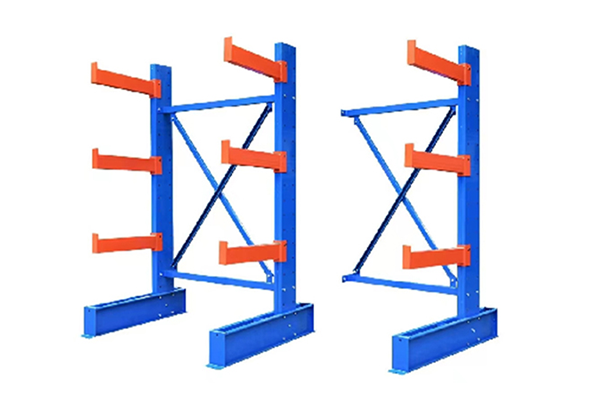

Designed specifically for extra-long or heavy irregular items, cantilever racking offers up to 3 tons of load capacity per arm. Its adjustable arms and column structure boost access efficiency for pipes, furniture panels, and similar goods by 200%. Chaoyu Racking's patented bolt design allows a full set to be installed in just 15 minutes.

You might still wonder if this truly addresses real-world issues. Let me share three customer stories to show how cantilever racking revolutionizes traditional warehousing.

Why Can't Traditional Shelving Handle 4-Meter-Long Steel Pipes?

In a 6-meter-high factory, Plant Manager Li could only stack million-yuan stainless steel pipes on the floor—until rust and deformation caused six-figure losses.

Cantilever racking's open-front design and unobstructed structure easily accommodates 2-8 meter ultra-long items. Chaoyu's specially developed 45-degree diagonal bracing system enhances overall stability by 70% compared to standard racks.

To meet diverse industry needs, we offer tiered configuration options:

| Industry Type | Recommended Configuration | Key Advantages |

| Building Materials Wholesale | Double-layer cantilever + electric forklift aisle | Accommodates 1.2m diameter cement pipes |

| Furniture Manufacturing | Rotatable arm system | Effortless 360-degree access to 2.5m panels |

| Mechanical Processing | Heavy-duty columns + anti-collision corner guards | 3-ton load per arm for stamping molds |

On-site testing shows that after adopting our V-shaped cantilever solution, an auto parts factory reduced mold retrieval time from 45 minutes to just 8 minutes.

Is Cantilever Racking Really More Cost-Effective Than Floor Stacking?

"It's just a few iron frames, right?" That was Manager Wang's initial reaction. But after reviewing his quarterly warehouse audit report, his perspective shifted completely.

Chaoyu customer data reveals that switching to cantilever racking delivers:

- 140% increase in warehouse utilization

- 82% reduction in goods damage rates

- 60% decrease in loading/unloading labor costs

We once customized a solution for a Kazakhstan client:

- Expanded column spacing from the standard 3 meters to 5 meters, compatible with Russian-standard forklifts

- Orange electrostatic powder-coated surface for better visibility in dim warehouses

- Integrated LED material identification strips

This ultimately helped the client recover their full investment within 12 months.

Is Installing This Professional Racking System Really a Hassle?

"We only have two maintenance workers on site..." That was Supervisor Zhang's main concern. As it turned out, he was worrying unnecessarily.

Chaoyu's modular custom shelving design makes assembly as straightforward as building with LEGO:

- All connection points use anti-loosening bolts

- Each arm features numbered labels for easy identification

- AR visualization guides provided for step-by-step installation

Our service network spans 136 countries, offering:

- Lifetime free structural safety consultations

- 2-hour response time for leveling requests

- Complimentary annual load-bearing inspections

Even a client in Chile received air-shipped replacement parts from us after a volcanic eruption.

Conclusion

With 23 years of dedicated focus, Chaoyu understands your warehousing pain points better than anyone. Click now to get your free 3D warehouse layout plan—and give your goods the reliable home they deserve.

This is the last one.

English

English