How Automated Rack Storage Systems Improve Space Utilization and Inventory

Dec 18 , 2025

In modern warehouses and distribution centers, the ability to optimize storage space while maintaining efficient inventory management is crucial for operational success. Automated rack storage systems have emerged as a transformative solution, allowing businesses to maximize space utilization, reduce labor costs, and improve the accuracy of inventory tracking. By incorporating advanced technologies such as robotics, artificial intelligence, and automation, these systems streamline warehouse operations, ensuring that goods are stored and retrieved quickly and efficiently. This article explores how automated rack storage systems enhance space utilization and inventory management, providing significant benefits to warehouses and logistics operations.

Maximizing Space Utilization with Automated Rack Storage Systems

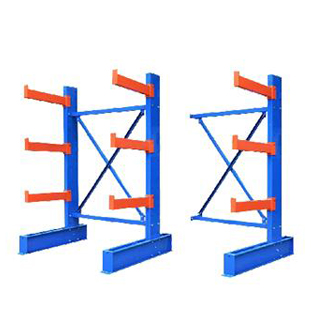

One of the primary advantages of automated rack storage systems is their ability to maximize available storage space. In traditional warehouses, storage often relies on static shelving or pallet racking systems, which can leave a significant amount of unused space. Automated rack storage systems, on the other hand, are designed to make use of vertical space and minimize wasted floor area. These systems employ high-density shelving that adjusts automatically to accommodate varying item sizes and quantities, allowing for optimal use of the warehouse's cubic footage.

Automated systems like fully automatic intelligent 3D warehouses can significantly increase the storage capacity within a given space. Through automated shuttle systems and robotic arms, goods are efficiently placed and retrieved from shelves without the need for human intervention. This ability to store items in compact, vertical spaces ensures that warehouses can accommodate more inventory without requiring larger facilities or extensive redesigns. The automated racks are also flexible, capable of being reconfigured or expanded to meet the evolving needs of businesses as their inventory grows.

Improved Inventory Management and Accuracy

Efficient inventory management is vital for any warehouse operation, and automated rack storage systems offer enhanced control and accuracy. With traditional manual systems, inventory tracking can be prone to human error, resulting in misplaced items, incorrect stock levels, or delays in stock retrieval. Automated rack systems eliminate these issues by integrating with warehouse management software (WMS) to track each item's exact location in real-time. The system ensures that all products are properly cataloged, stored, and retrieved in a precise, automated process.

The combination of automated rack storage systems and advanced software allows businesses to achieve a higher level of accuracy in inventory counts and improve stock rotation. By automatically updating inventory levels as items are moved in and out of storage, businesses can avoid stockouts and overstocking, ensuring that their products are always available when needed. Furthermore, the system can provide real-time data on stock levels, expiration dates, and order fulfillment, which helps streamline procurement processes and reduces the risk of inventory loss or mismanagement.

Enhanced Efficiency and Faster Retrieval Times

Speed and efficiency are critical factors in warehouse operations, especially in fast-paced environments like e-commerce and manufacturing. Automated rack storage systems help improve the efficiency of inventory retrieval, reducing the time workers spend searching for and retrieving products. Automated systems use robotics and shuttles to quickly transport items from storage to picking areas, allowing for faster order fulfillment and reducing wait times for customers.

In traditional systems, workers must manually navigate aisles and physically retrieve items, which can be time-consuming and labor-intensive. In contrast, with automated rack storage systems, goods are automatically delivered to the picking station, allowing workers to focus on order processing and packing. This automation not only speeds up the retrieval process but also reduces the risk of human error and improves overall operational productivity.

Flexibility and Scalability for Growing Operations

Another significant benefit of automated rack storage systems is their flexibility and scalability. As businesses grow and their inventory needs change, automated rack systems can easily adapt to new requirements. The modular design of many systems allows for quick reconfiguration or expansion to accommodate additional stock or new product lines. Whether a business needs to add more shelving units or expand the vertical space available for storage, automated systems can be scaled up or down with minimal disruption to warehouse operations.

This scalability makes automated systems an excellent choice for businesses that experience fluctuations in inventory volume or need to adjust their storage methods to keep up with demand. With the ability to adjust storage configurations as needed, businesses can continue to optimize their warehouse space and ensure that their storage system evolves with their needs, without having to invest in entirely new infrastructure.

The Role of Automation in Reducing Labor Costs and Improving Safety

In addition to improving space utilization and inventory management, automated rack storage systems also contribute to labor cost savings and enhanced safety in the workplace. By automating tasks such as sorting, retrieving, and storing goods, businesses can reduce their reliance on manual labor, thereby cutting down on labor costs. This automation not only leads to cost savings but also improves employee productivity, as workers are freed from performing repetitive, physically demanding tasks and can focus on more complex or value-added work.

Moreover, automated rack storage systems contribute to a safer working environment by reducing the risk of workplace injuries. In traditional warehouses, workers are often required to lift heavy items or navigate narrow aisles, increasing the likelihood of accidents. Automation minimizes the need for physical interaction with stored goods, which lowers the risk of injuries and allows workers to operate in a safer, more controlled environment.

Conclusion

Automated rack storage systems are revolutionizing warehouse management by improving space utilization, enhancing inventory management, and increasing operational efficiency. By leveraging automation and advanced technologies, these systems provide businesses with a scalable, flexible, and cost-effective solution for managing inventory and optimizing warehouse space. From improved speed in order fulfillment to better accuracy in stock management, the advantages of automated rack systems are clear. With the growing demands of modern logistics and supply chains, businesses that implement automated rack storage systems are better positioned to meet these challenges and stay competitive in an ever-evolving market.

English

English