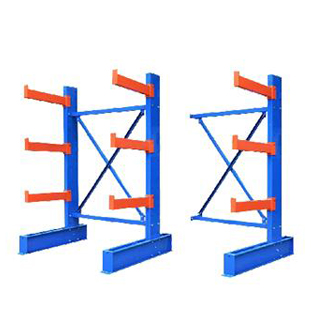

What is Cantilever Racking?

May 29 , 2025

Cantilever racks are a type of heavy-duty racks. Cantilever racks are suitable for storing long materials, circular materials, furniture panels, pipes and irregular goods. The cantilever wall can be single-layer or double-sided. Cantilever racks have stable structure, good load-bearing capacity and high space utilization.

The height and width of cantilever racks are usually within 2.0 meters (if the goods are stored by electric forklifts, it can reach 6 meters), the length of the cantilever wall is within 1.5 meters, and the load-bearing capacity of each arm is usually within 800KG. Cantilever rack uprights are mostly made of H-shaped steel or cold-rolled channel steel, and the cantilever wall is made of square steel pipe, cold-rolled channel steel or H-shaped steel. The cantilever wall and the uprights are connected by plug-in or screw connection, and the base and the uprights are connected by threaded connection. The base is made of cold-rolled channel steel or H-shaped steel. For storing heavy, scattered or other special goods, cantilever racks are an ideal solution. Cantilever racks are divided into double arms and upper arms, and can efficiently store similar goods such as wood, pipes, and bars. Cantilever shelves are made by placing external cantilever walls on the support of traditional warehouse shelves. They are a type of warehouse shelves specially designed for long objects.

Cantilever shelves are mostly used in machinery manufacturing fields and building materials malls. After adding storage boards, they are particularly suitable for warehouses with small indoor spaces and low relative heights. They are easy to manage, have wide sight lines, and have a higher utilization rate than ordinary warehouse shelves.

This is the first one.

English

English